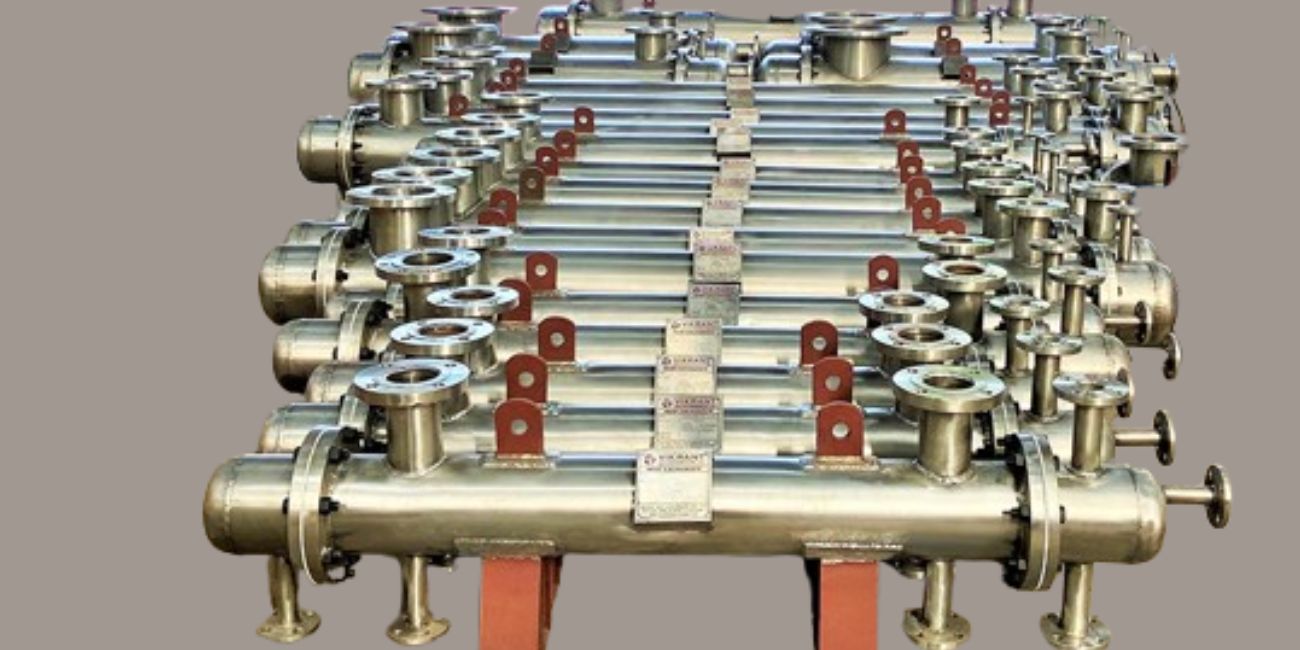

At Nisha Heat Exchangers we manufacture shell and tube Condensers which are used for any brine or water cooling application with Ammonia. These Condensers are available from 12 to 48 inches in diameter with tube length to 18 feet. Multiple bonnets are designed for 2 thru 10 liquid passes to provide maximum selection flexibility. With multiple shell arrangements, Shell and Tube Condensers may be installed in any size refrigeration system. Supported by the excellent manpower in the industry of air ventilation equipment manufacturing, we proudly offer a range of highly functional Shell and Tube Condensers.

Technology of frequency conversion is used in these products to enhance their functionality and lower the noise generated during operations. Protected to overflow of current these condensers are manufactured using copper tubes of superior quality. Available with a capacity range of 5 TR to 200 TR, are offered after conducting stringent quality tests ensuring zero leakage guarantee. Shell and Tube Condensers are provided with features of frequency conversion technology, low noise and more stable operation.

The shell is a large, robust vessel that enclose the tube bundle. The shell also has inlet and outlet ports for the entry and exit of the fluid.

The tube bundle is composed of multiple tubes, which are usually made of material that provide good thermal conductivity, such as Stainless Steel, Titanium, Hastelloy, Inconel, Monel, Nickel 200, Duplex, Super Duplex, Cu-Ni alloys, The tubes can be arranged in various configuration, including parallel, U-shaped, or helical designs. The choice of tube arrangement depends on factors such as the desired heat transfer efficiency, flow rate, and space limitations.

During operation, the two fluids pass on opposite sides of the tube walls, creating a temperature gradient. Heat is transferred from the hotter fluid (process fluid) to the colder fluid (service fluid) through the tube walls via conduction. The large surface area provided by the numerous tubes facilitates efficient heat transfer between the two fluids.

Sheel and tube heat exchangers are widely used in various industries due to their versatility, reliability, and efficiency. They are commonly found in applications such as power generation, chemical processing, oil refining, HVAC systems, refrigeration, and many other thermal processes.